SILOXANS IN BIOGAS.

ORIGIN, EFFECTS AND TREATMENTS

BIOGAS FROM LANDFILLS, DIGESTION AND WASTEWATER TREATMENT PLANTS (WWTP) IS A VALUABLE MATERIAL FOR THE PRODUCTION OF ENERGY, BIOFUELS AND THE PRODUCTION OF CHEMICAL PRODUCTS SUCH AS HYDROGEN AND METHANOL. AS IT IS A SOURCE OF RENEWABLE ENERGY, IT IS INEXHAUSTIBLE, CLEAN AND CAN BE USED AS PLANNED. THEIR USE GENERATES LESS ENVIRONMENTAL POLLUTION AND CONSTITUTES A VIABLE ALTERNATIVE TO THE ALREADY SENSITIVE DEPLETION OF FOSSIL ENERGIES, SUCH AS NATURAL GAS AND OIL, WHERE THEIR PRICES ARE ALREADY MAINTAINING AN INCREASE.

FROM A TECHNICAL POINT OF VIEW, BIOGAS IS A MULTICOMPONENT MIXTURE OF GASES, BOTH IN ITS BASIC COMPOSITION (CH4, CO2, H2, O2, N2, WATER STEAM, ETC.) AND ITS HARMFUL COMPONENTS (NH3, SILOXANES, HYDROCARBONS HALOGENATED, BTEX, VOCS, H2S, ETC). ITS COMPOSITION IS INTIMATELY RELATED TO THE TYPE OF MATTER THAT IS SUBJECTED TO THE ANAEROBIC DIGESTION PROCESS, AND A CERTAIN EXTENT, TO THE TECHNOLOGY USED FOR ITS PRODUCTION.

UNCONTROLLED SYSTEMS. LANDFILL BIOGAS, LANDFILLS, SWAMPS

CONTROLLED SYSTEMS. URBAN WASTEWATER TREATMENT PLANT (WWTP) AND ANAEROBIC DIGESTION PLANTS (HIGH ORGANIC LOAD).

IN GENERAL TERMS, IT CAN BE SUGGESTED THAT THE LATTER ARE CHARACTERIZED BY HAVING A HIGH CONCENTRATION OF H2S, ITS MAIN CONTAMINANT COMPONENT, AND, IN THE CASE OF WWTP, THE PRESENCE OF SILOXANES, WHILE THE FIRST ARE CHARACTERIZED BY THE APPEARANCE OF SILOXANES AND HYDROCARBONS. HIGH MOLECULAR WEIGHT.

SILOXANES COME FROM SILICONES THAT ARE PRESENT IN MATERIALS SUCH AS SHAMPOO, SOAPS, SURFACTANTS, OILS, PHARMACEUTICAL PRODUCTS, ETC., WHICH ARE SUBJECTED TO THE ANAEROBIC DIGESTION PROCESS.

SILICONES ARE MACROMOLECULES CONTAINING A POLYMER STRUCTURAL ELEMENT OF ALTERNATE SILICONE AND OXYGEN ATOMS WITH ORGANIC LATERAL GROUPS, SUCH AS METHYL, PHENYL OR VINYL, COMBINED WITH THE SILICONE. THE WORD SILOXANE IS DERIVED FROM THE WORDS SILICONE, OXYGEN AND ALKANE. SILOXANES ARE VOLATILE LIQUID COMPOUNDS AND TEND TO BE QUITE PERSISTENT IN THEIR ENVIRONMENTS.

FROM THE PROCESS POINT OF VIEW, IT CAN BE STATED THAT BIOGAS IS THE GAS PRODUCED FROM THE ANAEROBIC DIGESTION PROCESS OF THE ORGANIC FRACTION OF DIFFERENT TYPES OF MATTER AND THAT IT IS CHARACTERIZED BY ITS HIGH CONCENTRATION OF METHANE (CH4), WHICH IS WHAT GIVES IT ITS CHARACTERISTIC AS BIOFUEL. FINDING THIS CONCENTRATION BETWEEN 40 TO 80% V/V OF THE GAS GENERATED IN SAID PROCESS.

ON THE OTHER HAND, EVERY BIOGAS USE/RECOVERY INSTALLATION HAS THREE FUNDAMENTAL PARTS: BIOGAS PRODUCTION (AD SYSTEM), COLLECTION-CLEANING AND RECOVERY SYSTEM (ELECTRICITY, STEAM, BIOFUELS OR AS RAW MATERIAL FOR THE PRODUCTION OF OTHER PRODUCTS). ).

ALL THESE STAGES ARE CONSECUTIVE, THAT IS, THEY WORK ONLINE WITH A SPECIFIC FUNCTION EACH. IN IT, THE CLEANING/CONDITIONING OF BIOGAS AND ITS TECHNOLOGIES PLAY A FUNDAMENTAL ROLE AS IT GUARANTEES:

1.- AN OPTIMAL FUNCTIONING OF THE EQUIPMENT AND MACHINES (ENGINES, TURBINES, BOILERS, FUEL CELLS) INVOLVED IN ITS USE AS FUEL MATERIAL.

2.- A LONG USEFUL LIFE OF THE MACHINES USED FOR BIOGAS TRANSPORTATION, EXTRACTION AND COMPRESSION (BLOWERS AND COMPRESSORS).

3.- AN IMPROVEMENT IN THE EXHAUST GAS EMISSIONS OF THE MACHINES INVOLVED IN ITS ENERGY USE, BECAUSE IT ELIMINATES ITS CAUSE BEFORE ENTERING THE PROCESS.

4.-REDUCTION IN THE MAINTENANCE COST (REPAIR AND OIL CHANGE) OF THE MACHINES INVOLVED IN THIS TYPE OF INSTALLATION.

ORIGIN.

AMONG THE COMPONENTS WITH THE HIGHEST IMPACT ON THE ENERGY USE OF BIOGAS GENERATED IN TREATMENT PLANTS AND LANDFILLS ARE THE SILOXANES, WHICH CAUSE DAMAGE TO THE MACHINE USED, REDUCING THEIR USEFUL LIFE DUE TO THE ABRASIVE EFFECT THAT THEY PRODUCE ON THEIR INTERNAL PARTS, AS WELL AS THE OPERATING COST INCREASES DUE TO THE REPEATED CHANGES OF OILS AND INTERNAL PARTS OF THE SAME.

SILOXANES ARE A FAMILY OF ORGANIC COMPOUNDS FORMED BY LINEAR OR CYCLIC CHAINS OF SILICON, OXYGEN AND METHYL GROUPS. THEY ARE MANUFACTURED IN A RANGE OF FORMS, INCLUDING HIGH AND LOW VISCOSITY FLUIDS, RUBBER, ELASTOMERS AND RESINS, THEY ARE FOUND IN SIGNIFICANT QUANTITIES IN A WIDE AND VARIED RANGE OF DOMESTIC PRODUCTS, SUCH AS DETERGENTS, SHAMPOOS, DEODORANTS, PASTE TOOTHPASTE, COSMETICS, AMONG OTHERS.

MOST OF THEM RAPIDLY VOLATILIZE TO THE ATMOSPHERE AND DEGRADE OVER TIME INTO CARBON DIOXIDE, SILICA AND WATER. BUT SOME, HOWEVER, END UP IN WASTEWATER AND URBAN SOLIDS FROM DISPOSAL AND THEIR INEVITABLE ACCUMULATION IN LANDFILLS AND TREATMENT PLANTS, WHERE THEY ARE CONSIDERED ONE OF THE MOST DIFFICULT POLLUTANTS TO CONTROL.

THESE ARE ORGANIC COMPOUNDS FORMED BY SILICONES, OXYGEN AND METHYL GROUPS WITH STRUCTURAL UNIT –(CH3)2SIO, AND MOLECULAR WEIGHT TYPICALLY IN THE RANGE BETWEEN 150 AND 600. THEIR SOLUBILITY IN WATER DECREASES WITH THE INCREASE OF THEIR MOLECULAR WEIGHT AND THEY MAY OR MAY NOT BE VOLATILE.

SILOXANES ARE CHEMICAL COMPOUNDS PRESENT IN COSMETIC PRODUCTS, DEODORANTS, WATER-REPELLENT WINDSHIELD COATINGS, FOOD ADDITIVES AND SOME SOAPS. THEY ARE OFTEN USED TO SOFTEN COSMETIC PRODUCTS, OR AS A CHEMICAL BUILDING BLOCK FOR SILICONE-BASED RUBBER AND OILS. A FAMOUS SILOXANE APPLICATION IS WHAT IS KNOWN AS “SILOXANE SEALANT”: A WATER-BASED SPRAYABLE LIQUID USED TO WATERPROOF CONCRETE OR BRICK WALLS IN GENERAL.

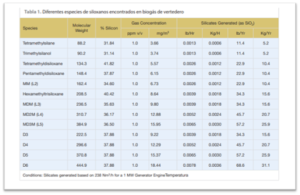

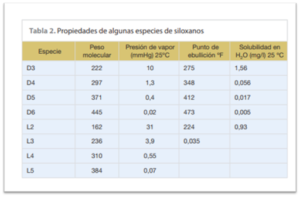

TABLES 1 AND 2 SHOW DIFFERENT SPECIES OF SILOXANES FOUND IN LANDFILL AND WWTP BIOGAS, AS WELL AS SOME OF THEIR BASIC PROPERTIES.

TABLE 1. DIFFERENT SPECIES OF SILOXANES FOUND IN LANDFILL BIOGAS.

TABLE 2. PROPERTIES OF SOME SPECIES OF SILOXANES.

EFFECT.

SILICONES, UNLIKE SULFIDES, DO NOT REACT WITH WATER TO FORM ACIDS; HOWEVER, DURING COMBUSTION, SILOXANE MOLECULES BREAK DOWN, AND RELEASE OXYGEN AND SILICON; THE LATTER IS COMBINED WITH OTHER ELEMENTS FORMING SILICATES, SILICA AND OTHER CRYSTALLINE COMPOUNDS THAT ARE DEPOSITED IN THE COMBUSTION CHAMBER (MAINLY ON THE TOP OF THE SHIRT), THE CYLINDER HEAD AND THE FACES OF THE VALVES.

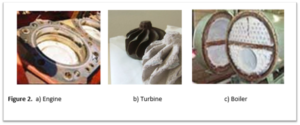

THESE ENCRUSTATIONS CAUSE ABRASION WEAR IN DIFFERENT INTERNAL PARTS OF THE ENGINES. FIGURE 2 SHOWS THE SCALING CAUSED BY SILOXANS IN DIFFERENT TYPES OF MACHINES.

THE PERMISSIBLE CONTENT OF SILICONES FOR THE GOOD FUNCTIONING OF THE GENERATION ENGINES SHOULD NOT EXCEED IN GENERAL< 5 MG/NM 3 , ALTHOUGH EACH MACHINE MANUFACTURER SETS ITS LIMITS. A HIGHER CONTENT WILL INDICATE POSSIBLE SILICA DEPOSITION PROBLEMS, AND WITH IT, THE BURNING OF THE EXHAUST VALVES. IN THE CASE OF TURBINES, THIS PROBLEM IS OF GREAT INTEREST GIVEN THE HIGH NUMBER OF REVOLUTIONS (RPM) AT WHICH THE IMPELLER OF THIS TYPE OF MACHINE TURNS, SO ANY IMBALANCE DUE TO ITS WEIGHT DUE TO THE SILICON ENCRUSTATIONS CAN CAUSE SEVERE PROBLEMS.

Figures 2. Fouling caused by siloxanes in different types of machines.

Treatments.

Current systems for the elimination of said compounds use techniques that generally have one or two stages involved, among which we can mention: subcooling, adsorption on activated carbon/silica gel, graphite filters, certain types of resins, washing with certain reagents (methanol, sulfuric acid, hydrocarbon mixture, etc.). However, the most applied techniques are listed below

Common techniques for the removal of siloxanes.

1.- Cooling.

- Up to 4ºC.

- Subcooling (cooling down to -25 ºC).

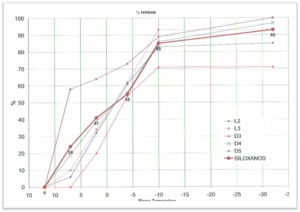

Figure 3 shows the effect of temperature on the reduction of siloxanes in Biogas

Figure 3. Research group work on siloxanes in biogas-2003.

2.- Adsorption.

- Activated carbon.

- Regenerative thermal/membranes.

- Silica gel.

3.-Washing with certain reagents. Methanol and used oils

4.- Combination of techniques. BTS-MPdry. Biolimp-Siloxa model.

BTS-MPdry. It is a multipurpose technology (cleaning/conditioning) developed by the Biogas & Gases Technologies (Energy & Waste) group. based on the combination of operations based on cooling, condensation, washing, drying and adsorption on activated carbon, which minimizes both energy consumption and activated carbon. The technology has two basic stages. One for gross removal of contaminants including type D siloxanes, hydrocarbons and biogas conditioning for entry to activated carbon filters by thermal means. Another refinement (removal of siloxanes type L and D) via adsorption on activated carbon. An important part of this technology is the scrubber recuperator that guarantees the conditioning of the biogas in all senses.

Another advantage of this technology is that it allows eliminating both heavy hydrocarbons and those containing chlorine or fluorine compounds, which in turn affects the proper functioning of the engine, as well as compliances with emissions of power generation systems.

The BTS-MPdry technology and other technologies developed for biogas cleaning is the result of the R&D work of the Biogas & Gases Technologies group (Energy & Waste S.L.), which has been working for more than 20 years on the cleaning and conditioning of different types of gases and, in particular, on biogas.

FIGURE 3. BTS-MPDRY. BIOGAS CLEANING PLANT. BUTARQUE-MADRID SOUTH WWTP