Wastewater treatment plants (WWTPs) are facilities that consume large amounts of energy (thermal and electrical), as a result of their operation, they produce large amounts of sludge. The anaerobic digestion of these sludges from wastewater treatment produces biogas, which, due to its concentration in methane (CH 4 ), constitutes a biofuel that can be used for energy production.

The best option for managing this gas, within the WWTPs, is its use in power generation. In this way, on the one hand, part of the energy needs of the WWTP are met and, on the other hand, greenhouse gas emissions are avoided.

Biogas is a mixture of gases, formed mainly by methane (CH 4 ), CO 2 , water vapour and traces of other components. Therefore, for adequate use of biogas, it is necessary to reduce its moisture content and separate from it all these harmful compounds in the useful life of the equipment involved in its use as biofuel.

For an adequate operation of the biogas cogeneration system, cleaning of this gas is required to eliminate its contaminants, with adequate operating costs and high cleaning efficiency.

Currently, the energy use of biogas generated in treatment plants is affected by the appearance of compounds, such as siloxanes and hydrogen sulfide (H 2 S), mainly and to a lesser extent by the appearance of different types of hydrocarbons.

The importance of biogas management can be summarized from the following points of view.

- Environmental . Avoid toxic and greenhouse gas emissions into the atmosphere (CO 2 , CH 4 , H 2 S).

- Energetic . Production of thermal and electrical energy, as well as material for the production of other fuels (NG, H 2 , Methanol).

- Management . The energy recovery of different types of waste carriers of organic load.

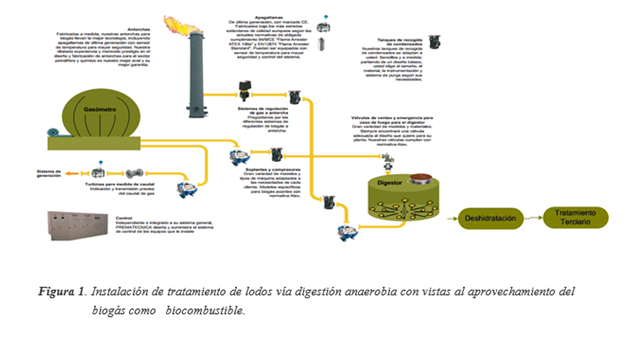

In general terms, a biogas installation has the following stages:

- a) Production/generation of biogas . Production system (landfill or biodigester).

- b) Collection and conditioning .

- c) Use/application . Power generation, biofuel production or chemical products.

The flow chart in Figure 1 shows a typical WWTP sludge treatment facility via anaerobic digestion, using biogas to meet the energy needs of the process itself and selling surplus energy to the grid.

Anaerobic digestion as a means of treatment and recovery of WWTP sludge.

Anaerobic biological processes. It is a process that degrades organic matter in the absence of oxygen. It is used to stabilize the sludge, transforming it into a suitable product for final disposal or processing with other treatments.

Traditionally, it was installed in large plants, but it is currently installed in smaller plants due to economic reasons (use of digestion gas).

This process does not require the supply of oxygen (which is an economic advantage). It allows the use of methane as fuel, and the sludge obtained is already stabilized. However, it requires a long start-up period if no inoculum is used. Besides, it is very sensitive to variations in environmental conditions, and its efficiency in removing organic matter is lower than in aerobic processes.

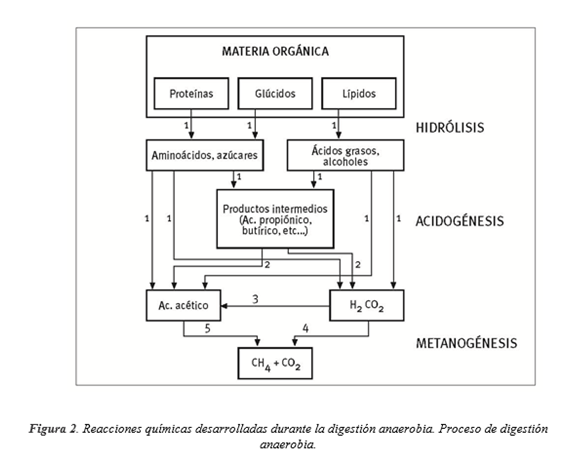

Bacterial fermentation of organic matter with methane production takes place in a closed area in the absence of air. The mud is composed mainly of carbohydrates, lipids and proteins. During anaerobic digestion, the following processes take place.

biogas production

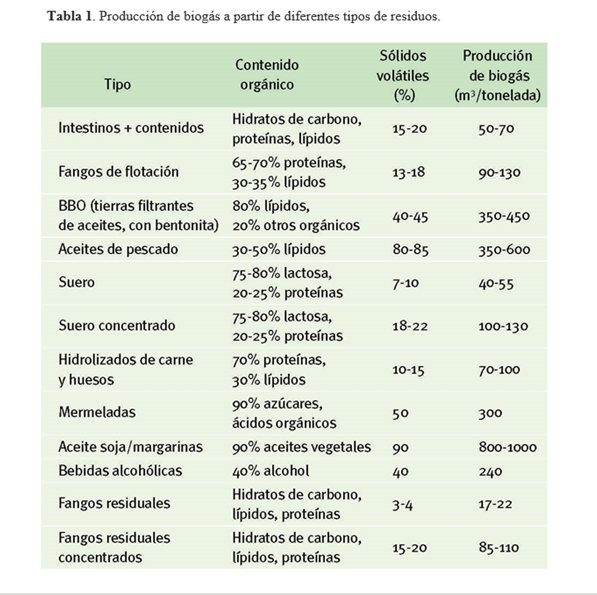

The production and composition of the biogas are closely linked to the organic load of the sludge to be treated and to the type of process chosen, as well as to the possible previous pre-treatments to which they are subjected before the digestion process.

The anaerobic digestion of this sludge produces a gas with an approximate content of %-65% methane (CH 4 ), %-40% carbon dioxide (CO 2 ) and other percentages of residual gases. In modern plants, the gas is stored in a gas holder and once subjected to a treatment to eliminate polluting or corrosive compounds, it is used as fuel in engines specially prepared to consume it.

The measurement of carbon dioxide is related to alkalinity and acidity, it is a good indicator of digestion stability.

Types of biogas and its composition.

Currently, we can talk about two basic types of biogas according to its origin.

- a) From an uncontrolled system, that is, from natural digestion, for example, the most classic, biogas comes from landfills: characterized by the basic presence of siloxanes↑, halogenated hydrocarbons ↑, humidity, ↑ and sometimes H2S, etc.

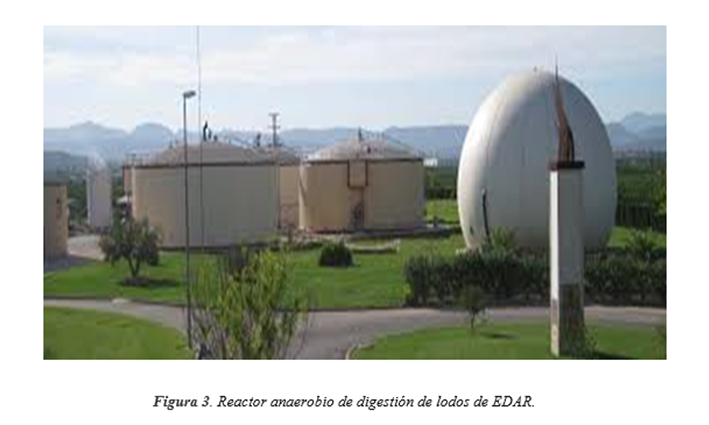

- b) Controlled system (biodigesters) . For example, biogases come from wastewater treatment plants (WWTPs). Production is carried out by means of different types of reactors (complete mix, plug flow, fluidized bed, etc.), psychrophilic processes (below 25°C), mesophilic (between 25 and 45°C) and thermophilic (between 45 and 65°C) and dry or wet process depending on the number of solids involved in the digestion process. Whichever process is selected, it will be controlled in terms of its fundamental process variables (temperature, pH, organic load, retention time, humidity, agitation, etc.). There are different teams where this process is developed. In this case, one of the most common is the stirred tank reactor.

In the latter case, depending on the substrate to be treated, we can find:

1) Wastewater (WWTP), characterized by the basic presence of (siloxane, H 2 S) ↑, humidity ↑, NH 3 , foams and particles, etc. It is the most complex of all due to the number of components that appear in it.

2) OFMSW biogas. When the substrate is made up of the organic fraction, they come from municipal solid waste (MSW). characterized by the presence of (H 2 S, NH3) ↑, humidity, etc.

3) Agro-industrial biogas. When by-products and waste from the agricultural, livestock or agricultural industry sectors are digested. of (H 2 S, NH 3 ) ↑, humidity, etc.

4) Biogas from the food industry. Meat waste, by-product of the brewing industry, dairy, etc. of (H 2 S, NH 3 ) ↑, humidity, etc.

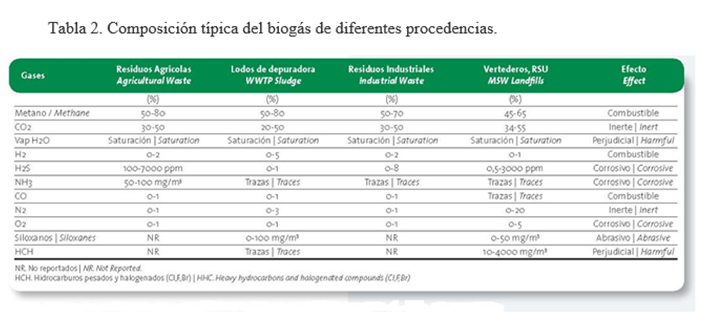

Table No. 2 shows the basic composition of some types of biogas mentioned above and the effect that each of its components has when used for energy purposes, depending on the substrate to be digested and the type of digestion (controlled or natural).

Biogas capture system.

Once produced, biogas reaches an overpressure inside the digester close to 20 mbar, a pressure that depends on the type of digester used, which allows it to leave the digester and reach the storage system (gasometer) if it is located on the gas line. biogas, i.e. outside the digester. But it does not have enough pressure for its conditioning and delivery to the cogeneration system (boilers, motors or turbines). For this reason, it requires a rise in pressure using a flow machine (blower), typical for this type of installation.

Before reaching the gasometer, the biogas from the biodigester must be removed from foam, sediment, particles and condensates that travel with it, which can cause the installation to malfunction, including the flow machine and the cogeneration system.

For this, foam breakers, gravel filters, particle filters and condensate pots are used to eliminate this type of impurities, typical of this type of WWTP biogas production facility.

This first cleaning is known as coarse cleaning since accompanying phases are removed from the flow of the biogas stream.

Biogas treatment system. Biogas cleaning or fine cleaning

Biogas is a mixture of gases, formed mainly by methane (CH 4 ), CO 2 , N 2 , O 2 , H 2 , CO, water vapour and traces of other components such as H 2 S, siloxanes, NH 3 , hydrocarbons and others that are part of the biogas flow. For proper use of this, it is necessary to reduce its moisture content and separate from it all the harmful compounds in the useful life of the equipment involved in its use as biofuel.

Among such compounds, we can mention hydrogen sulfide (H 2 S), ammonia (NH 3 ), siloxanes, heavy and halogenated hydrocarbons, and others that may appear as volatile fatty acids.

Water steam.

Water vapour drastically decreases the LHV of biogas; For this reason, the energy performance of the equipment involved in its use as biofuel (engines, turbines, boilers, burners, etc.) is affected. For this reason, before being used, it is appropriate to reduce its moisture content as much as possible by any method. In turn, this elimination is necessary to avoid the accumulation of condensate in the gas line and, with it, to avoid the formation of corrosive acids, as well as the clogging of the pipes due to accumulation and sometimes due to the formation of ice.

halogenated hydrocarbons.

Hydrocarbons, both high molecular weight (heavy), as well as halogenated ones, particularly those that have chlorine and fluorine, must be eliminated. These are mainly present in landfill gas. They cause corrosion in generation engines, mainly in the combustion chamber, valves and cylinder heads. Therefore, engine manufacturers request a maximum limit of halogenated hydrocarbons.

Hydrogen sulfide (H 2 S).

Biogas desulfurization is necessary to prevent corrosion and avoid toxic concentrations of hydrogen sulfide (H 2 S). When biogas is burned, sulfur oxides such as SO 2 /SO 3 are formed, which are even more poisonous than the H2S that gave rise to them. At the same time, SO 2 lowers the condensation point of the exhaust gas (fumes) and there is the possibility of the formation of sulfurous acid (H 2 SO 3 ), which is highly corrosive.

On the other hand, hydrogen sulfide (H2S) when mixed with the humidity of the air (water) or with the moisture of the biogas itself in the combustion chamber of the engines or boilers forms sulfuric acid (H2SO4) that attacks the different metallic parts of the same, particularly those containing copper (Cu), bronze, iron or other material, considerably reducing the performance of these parts.

In addition, in the case of engines, it contaminates the lubricant, producing emissions of sulfur oxides in the exhaust gases, which are harmful to the environment.

Siloxanes.

Among the components with the greatest incidence in the energy use of biogas generated in landfills and/or in treatment plants are siloxanes, which cause damage to the engines used, reducing their useful life due to the abrasive effect they produce on the internal parts of these.

This effect is due to the deposition of silica that occurs in the different parts as a result of the combustion that takes place in the internal part of the engine.

The production of energy or production of Biofuel.

The sewage treatment sludge from the primary and secondary treatments that are produced in the Water Treatment Plants (WWTPs) constitutes a valuable material for the production of energy or raw materials using anaerobic digestion technology, which is especially interesting when considering an energy application of biogas produced from the figure of 100,000 inhabitants.

Currently, the energy use of biogas generated from this type of waste has reached a significant degree of development, as well as its use for the production of biofuels (Biomethane or H 2 ).

The generation of energy (electricity and heat) using biogas as fuel can be carried out using different types of machines specially adapted to burn this type of gas with a low calorific value and a chemical composition that is very different from conventional fuels similar to natural gas.

Combustion of biogas for thermal use is less frequent than for electrical use and is mainly focused on the production of heat for heating the digester itself, which operates at a temperature of about 38 ºC.

The generation of energy (electricity and heat) using biogas as fuel can be carried out using different types of machines specially adapted to burn this type of gas with a low calorific value and a chemical composition that is very different from conventional fuels similar to natural gas.

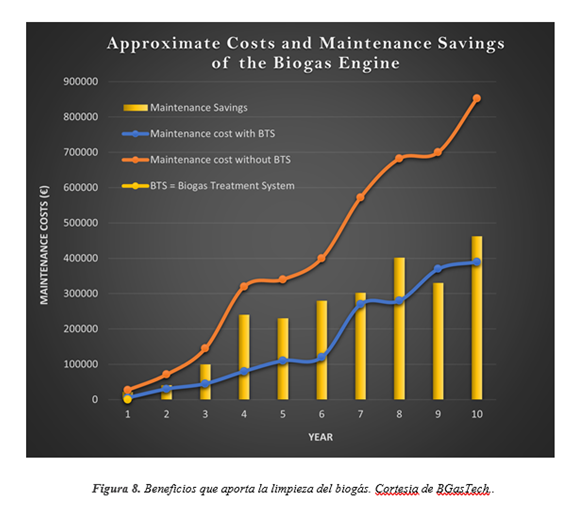

The benefits provided by the cleaning of biogas to the power generation system can be seen in figure 8, in which the possible income from improvements in the exhaust gases of the engine and with it the care of the environment are not taken into account.

State of the art in the use of biogas.

The new alternative to biogas, which has gained momentum, is its application and use in the production of Biomethane, a gas with characteristics similar to natural gas, high and constant PCI, and which has, in turn, opened up new applications for it.

Several technologies compete in the market for the production of Biomethane or biogas enrichment, that is, removal of CO 2 after cleaning. Among them can be mentioned.

- chemical absorption. Selective reagent (acid gases)

- physical absorption. Difference of solubilities.

Ø Water pressure and temperature

Ø Organic solvents.

- Molecular sieve. molecule size

- membranes. Permeability. dry distillation

- Cryogenic. triple point. Boiling point. Cold distillation.

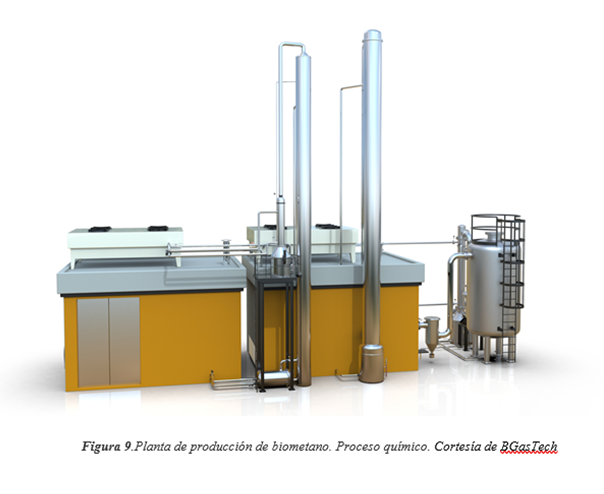

Figure 9 shows the BTS-Bio-CH 4 Technology for the production of Biomethane from biogas developed by the BGasTech group with more than 20 years of experience in the sector of the use and application of biogas.

Your group for turnkey projects for the solution in the treatment of biogas, gases and odours.

Our group of experts will

help you choose the technology that meets your needs.

Your ally in the engineering, construction, supply, development and application of renewable energies.